CHASSIS NUMBER ONE

Finally after weeks of searching, designing and plenty of cursing, Chassis Number One has finally arrived at the office! Its been surprisingly frustrating as the market for low volume customized chassis is hmmm... small. Luckily we did find a company in the US of A (of all places) which specializes in exactly that, low volume high quality custom chassis.

The chassis is 100% aluminum 1U 740mm deep, which is pretty unique by itself. The high level physical goals are simple, 1U and light weight. Expecting this device will be at the top of a 42U rack which means the DC Ops guys need to be comfortable moving the device without a forklift. By itself the chassis is very light, about 2.5KG, and fully loaded its well under 10Kg with the PSU the heaviest single component.

.. and on with it! The box it came in was massive but deceivingly light.

.. inside there was this sea of bubble wrap, with something black floating inside.

.. and then something shiny catches my eye! oh.... its so shiny... in a sleek matte gloss powder coat kind of way :)

.. from the back everything looks pretty good. probably need to shift the silkscreen down a little, and completely forgot about the GPS SMA connector. Capture port wording needs some work too.

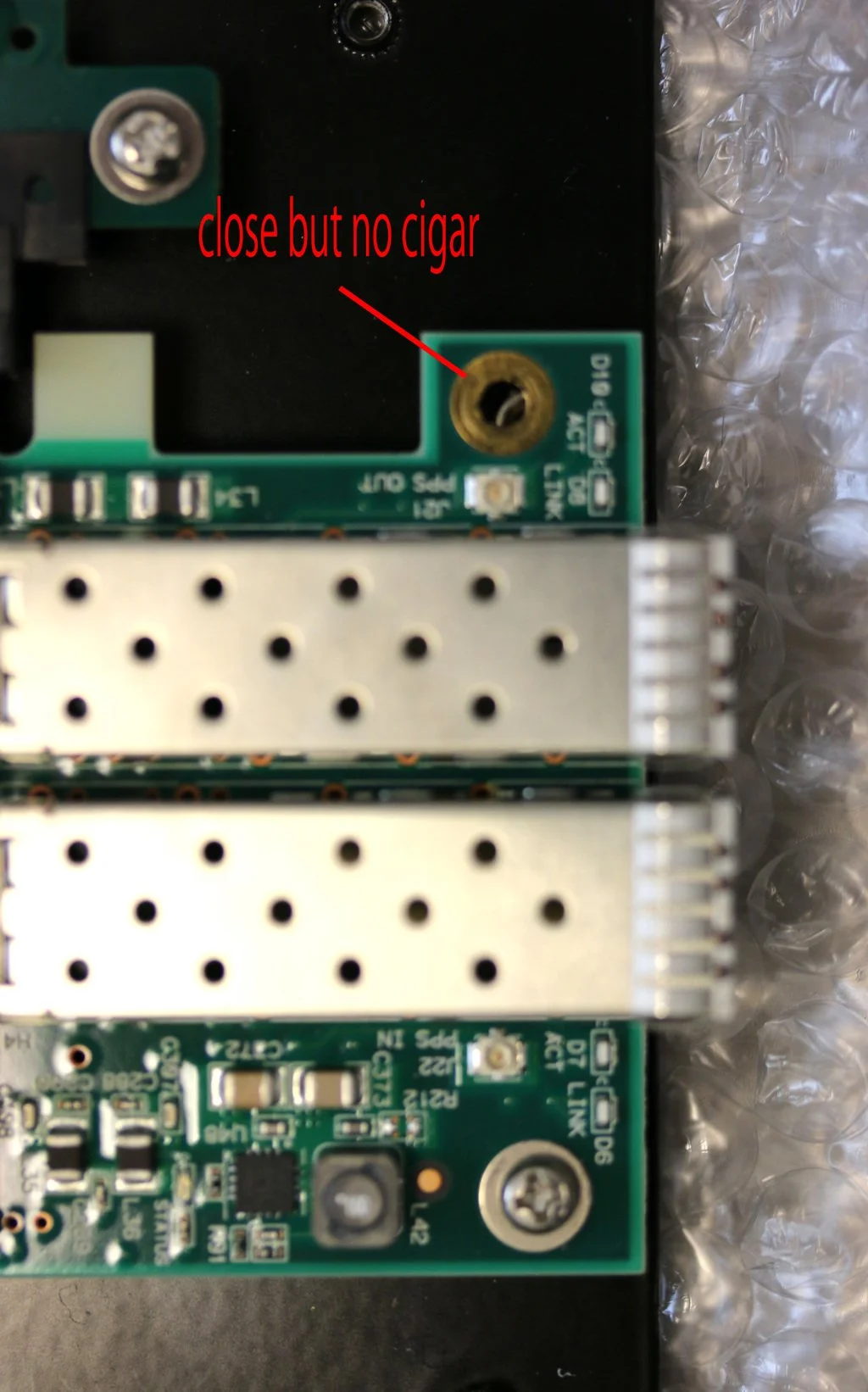

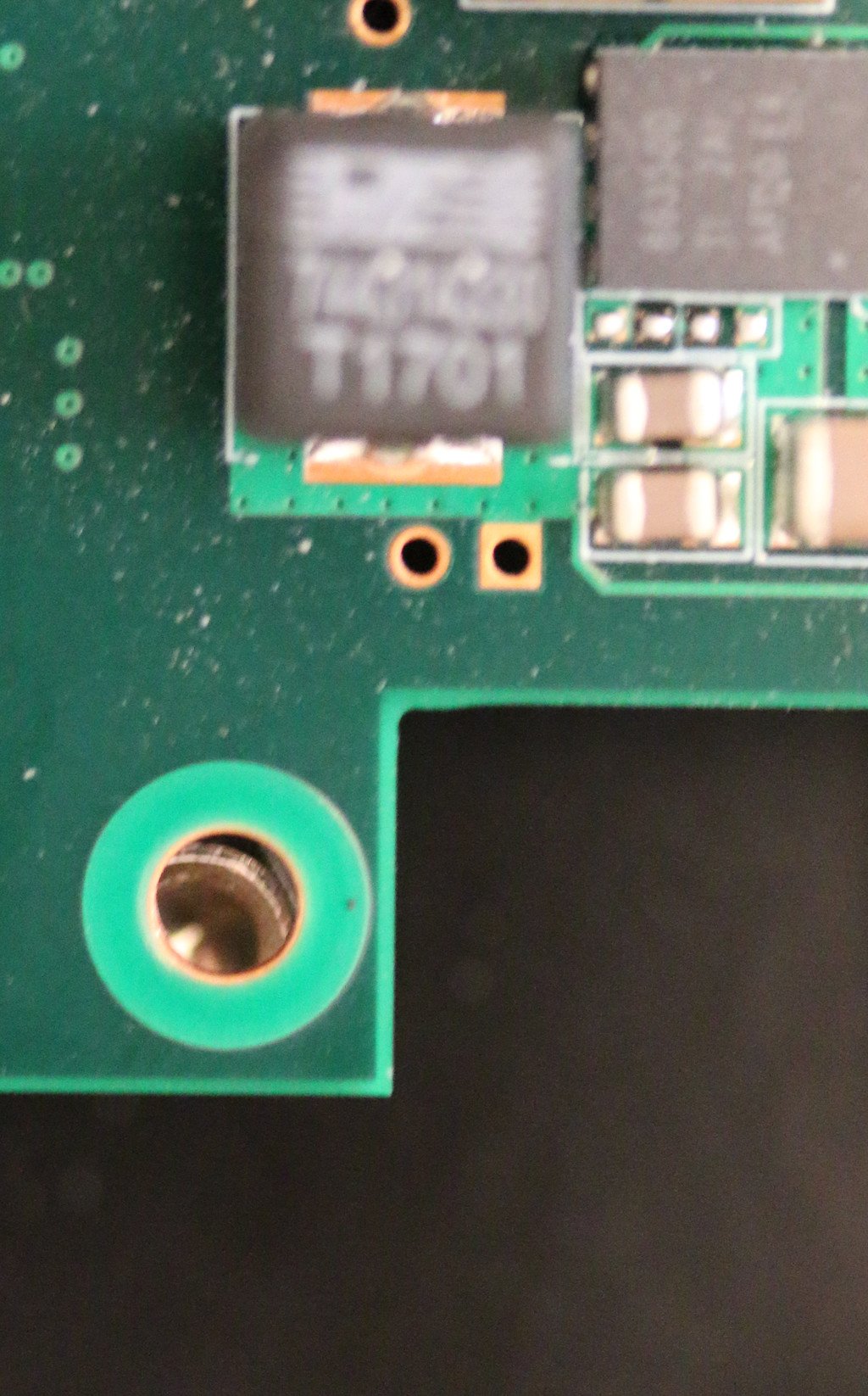

.. and then the moment of truth. Having spent at least 2-3 days setting up the design with CAD tools, and having measured every single PCB mounting hole twice, check and then re-check! its time for the PCB to hit the metal... Got about 80% of the mounting holes correct but its painfully obvious this should have been entirely digital from the start. Locations of the components (motherboard/pcie devices) PCB mounting holes should have been sourced from their respective CAD model.

As even 1mm or sub millimeter off is a recipe for disaster.

.. and a sub millimeter error below. So painful to see. These errors are actually the most dangerous as if you mount the screw here, the forces on the board will likely create a tiny fracture in the PCB causing all sorts of problems.

.. and the front panel? where`s the money shot ? is it the usual boring metal box that's been rubber stamped by the corporate marketing division ? ... hell no.

As its a well known scientifically proven fact that, everything painted red goes faster. And our hardware and software runs faster than the competition because its red... and our code kicks ass :)

What you can`t see is the monster air intake array behind the grill, a topic for a different post.

Chassis number two is a bugfix only version, fixing up the mounting holes and some other minor problems and hopefully the design is frozen. And finally have a user friendly box to demo with!